II" x II" Print Area -For Larger Thick Film Hybrid and SMT Printing Applications

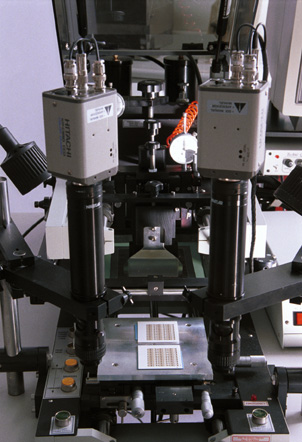

MPS's SP-1500 precision semi-automatic screen and stencil printer was developed to meet the needs of larger hybrid substrates, fine pitch patterns in surface mount technology (SMT), and printing polymers on PCBs and flex circuits. Although specifically designed to print thick film circuitry for hybrid microelectronic applications, its larger print area makes it ideal for many SMT and through-hole applications. As such, its flexibility makes it an exceptional value for its price.

The SP-1500 provides the high degree of precision and repeatability required for printing electronic circuitry in low volume, R&D and prototype applications. Its simplicity of setup and operation, as well as its rugged and durable design, and construction, make it well suited for medium and high volume production uses.

Flexible and Versatile Because of its extreme flexibility, the SP-1500 offers users exceptional cost/value advantages. The printer can accommodate a wide range of substrates from ceramic to epoxy/glass, and materials ranging from cermet and polymer thick film to solder paste, epoxies, and solder mask. The SP-1500 printer has Contact/Off -Contact printing capability , and accepts all standard screen and stencil frames.

Print

Mode Flexibility, Precise Control

Print

Mode Flexibility, Precise Control

The SP-1500 control module allows users to make a variety of print parameter adjustments for maximum flexibility and tighter control over printing results. For example, the Mode Selection Switch allows the operator to select any of four different automatic print cycles; Single print/flood/return, or flood/print; Alternate print mode with squeegee hop-over; and Double print. Solid state electronics provide years of reliable service with minimal maintenance. A variable "squeegee up" delay (up to 2 seconds) allows the screen to peel off behind the squeegee. An adjustable carriage return delay helps users obtain the best print images possible based on the specific characteristics of the various materials used. A digitized squeegee timer, parts counter, and system air pressure gauge are also standard on the SP-1500.

Fast

Setup, Easy Cleanup

Fast

Setup, Easy Cleanup

The SP-1500 offers two unique features that facilitate fast, easy setup. MPS's unique mylar alignment system provides rapid one-print registration of any pattern. In addition, MPS's unique 3-point frame registration system simplifies stencil or screen removal and cleaning. This feature permits the reinstallation of the same stencil or screen after cleaning without pattern realignment. Independent dial adjustments for screen height (snap-off) and squeegee down stop further speed setup. A pneumatically raised print head with a screen/stencil "tilt-away" feature provides full access to the screen and squeegee assembly for simplified screen/stencil replacement and cleanup. Additionally, because the SP-1500 is designed with a single squeegee and pre-set hop-over, setup as well as cleanup are easy and quick. The single squeegee design also increases the squeegee stroke length for maximum print area in all modes.

Copyright © 2001. MPS International, Inc. All rights reserved.